QR code

* Please scan the QR code with your smartphone to access this website page.

Operation Principle

Level measurement technology using microwaves is the flavour of the decade.

Level Gauges derived from this technology can roughly be classified into two types:

1. FMCW Type (Frequency Modulated Continuous Wave)

|

This Radar Level Gauge works like this:

A sensor (antenna) mounted on tank top radiates a microwave and detects the radiated microwave when it is reflected from liquid or solid surfaces. Ullage is calculated in time taken from radiation to reception of microwave, deducted from tank height and then converted into level data.

The theory is similar to that of ultrasonic level gauge which measures level by sound echo.

However, thanks to special features of microwaves, measurement is independent of such factors in the tank's internal atmosphere as temperature, pressure, steam, dust, etc. which otherwise tend to interfere with ultrasound.

However, the beauty of perfect non-contact measurement in this arrangement is marred by microwave characteristics of dispersion and attenuation which means that certain products cannot be measured.

2. TDR Type (Time Domain Reflectrometry)

|

To counteract the effect of microwave dispersion and attenuation, a probe protruding into the tank is provided to direct the microwave. The microwave is emitted intermittently from the electronics and propagates along the probe (a metal rod or cable probe) and reflects on the liquid surface back along the probe to the electronics. In this way, it is possible to conduct both level and interface measurement between two liquids by comparing the travel times from emission to receipt of the micro-pulse.

Difference of Operation principle between FMCW Type and TDR type

In case of Radar Level Gauge (FMCW), microwave generated from the electronics is directed to antenna through waveguide and propagated over open space inside the tank.

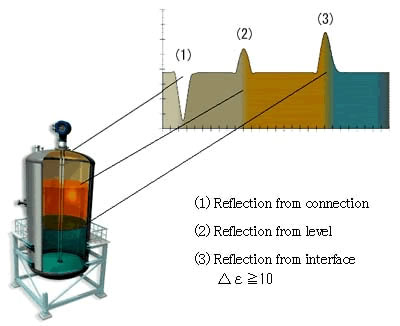

However, TGR-3000 series (TDR) does not propagate microwave over open space, but directs it down the probe in the tank.TGR-3000 measures the travel time of micropulse from emission to receipt of reflected pulse (due to dielectric constant) and computes the level.Differences in dielectric constant changes affect reflection rates of micropulse and wherever such differences occur, different reflection rates are propagated back along the probe to the electronics. Dielectric constant changes at installation part of probe; thus the electronics always receives reflection from the connection point. - - - Diagram (1) below

Taking level measurement of liquids as an example, inside the tank there is first a gas phase. In this case, the dielectric constant of normal gas phase er is 1 and micropulse penetrates this part and does not reflect. When micropulse reaches liquid surface, it reflects on the interface between gas phase and measured product due to the difference of the dielectric constants. - - - Diagram (2) below

Further, if there is another liquid lower still and the differential of the dielectric constants of upper and lower liquids is of more than a specified value, the micropulse reflects on their interface. - - - Diagram (3) below

Thus level is measured by reflection of micropulse due to the difference in the dielectric constant. The reflected pulses are emitted back to the electronics at different time intervals and level or interface is measured by the time travelled. The dielectric constant of the measured product is the determining measurement factor; thus, the type of application product (liquid, powder, pellet, etc.,) is irrelevant.

The electronics have the following special features:

Emission of micropulse is intermittent

Receiving circuit must have short and fast start ups as time intervals are very brief.

Measurement of intensity distribution of micropulse along the probe

Detection of reflected pulse

The electronics receives only short time domain per pulse in this type; for this reason, it is called time domain.

(This same method is now used to locate damaged parts of communication cables). Thanks to the probe, the efficiency of the micropulse propagation is high and dense compared to non-contact type (FMCW). Thus only low energy is required even for the measurement of low dielectric constant products.

Diagram Example of TDR type reflection

Non-moving part construction

Measurement unaffected by Temperature or Pressure

Thanks to the probe, measurement in narrow spaces such as pits is possible.

Max. temperature of process connection part : 150°C, Max. Pressure : 4 MPa

Probe material is selectable for wide range of corrosive liquids

Wide range of application liquids and solids

Level and/or interface measurement

In addition to direct mode for normal application, TBF (Tank Bottom Following) mode is available for very low dielectric products such as liquefied gases, liquid nitrogen, plastics pellets, sawdust, cement, etc.

Level and interface can be measured simultaneously and output

TDR type Guided Radar Gauge TGR-3000 Series is a Radar Level Gauge whose antenna is inside the tank

1. When replacing other measuring instruments

TDR type level gauge can replace the following instruments satisfactorily at competitive prices and with enhanced functions and capabilities:

· Differential pressure level transmitter (Flange type, Immersion type, Purge type)

· Ultrasonic level meter

· Capacitance type level meter

· Displacement type level transmitter

2. For difficult measurement specifications

TDR type level gauge can be specified for difficult applications:

· Interface between 2 liquids

· Silos for solids

· Liquefied gas (TBF mode)

· Liquid ammonia

Microwave level gauge is expected to expand the range of available level gauges. Even though the TDR type TGR-3000 Series Guided Radar Gauge is contact type, it has unique advantages and capabilities and is selectable for a wide range of applications.

* Please scan the QR code with your smartphone to access this website page.